I have a gantry router that is stepper driven. I built it a few years ago to do a specific job for a customer and it served that purpose just fine. Unfortunately the work for that machine has dried up so I'm trying to use it for some of the smaller patterns I do. When it's cutting G2/G3 arcs there is a noticeable shake along with a choppy cut. I use a waterline profiling strategy with a .005" step down and the chop lines up the whole way down the piece so it's not intermittent or random. It's like it's stuttering when it tries to do combined XY moves.

The router is rack and pinion drive with X and A slaved. I have all of the axis acceleration settings the same. I'm attaching the .PRO. I would really appreciate it if someone could take a look at it and see if there are any glaring errors in my setup. I'm not well versed on stepper setups. The drives and power supply came from CNCrouterparts and was one of their NEMA23 4 motor plug and play stepper kits.

Thanks

Derek

Choppy motion on arcs

10 posts

• Page 1 of 1

Choppy motion on arcs

- Attachments

-

Sheet_Router.pro

Sheet_Router.pro- (28.77 KiB) Downloaded 683 times

- Derek

- Posts: 341

- Joined: Mon Sep 05, 2016 9:57 am

Re: Choppy motion on arcs

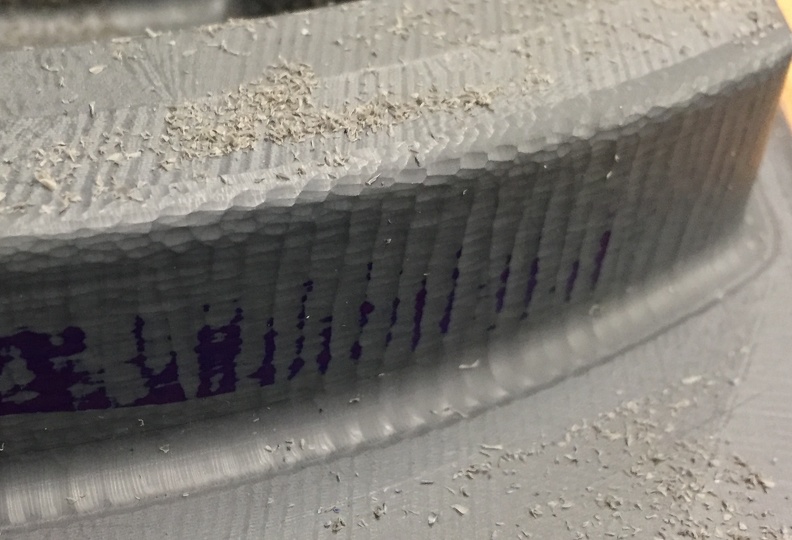

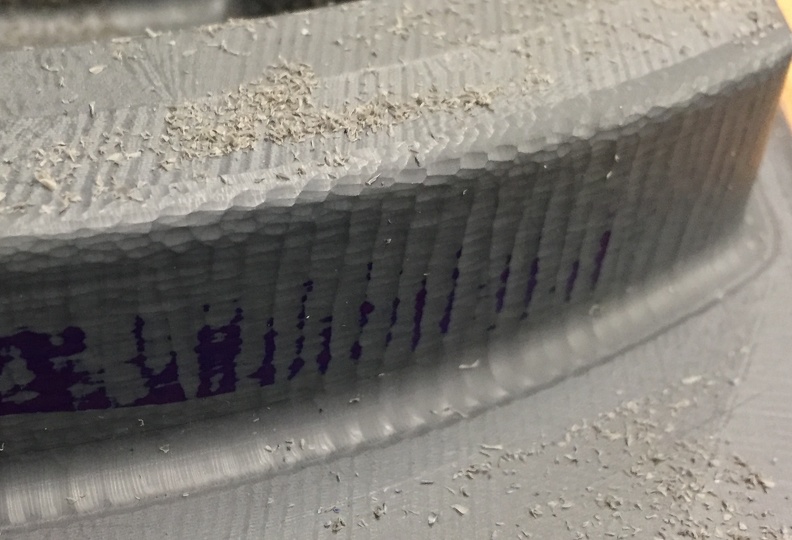

Here is a picture of what I am talking about. For reference the piece you are looking at is .75" tall. So at a .005 step down is 150 passes and you can see that the chop is all in a line for the most part. I'm using a .25" ball nose for cutting.

- Derek

- Posts: 341

- Joined: Mon Sep 05, 2016 9:57 am

Re: Choppy motion on arcs

Badly adjusted rack to pinion often do this stuff. I saw it many times.

Post your g-code and tell me about at which line number is the issue and then we will measure out the step/dir signals, but I don't think the problem will be with UCCNC or your settings. Your CV settings are low enough to not allow the large chops as on your picture.

But anyways we will be happy to measure the signals out, just post the g-code...

Post your g-code and tell me about at which line number is the issue and then we will measure out the step/dir signals, but I don't think the problem will be with UCCNC or your settings. Your CV settings are low enough to not allow the large chops as on your picture.

But anyways we will be happy to measure the signals out, just post the g-code...

- cncdrive

- Site Admin

- Posts: 4887

- Joined: Tue Aug 12, 2014 11:17 pm

Re: Choppy motion on arcs

Here is the file.

There is only .004" backlash measured with a dial indicator on X and Y. Is this what you mean as far as adjustment? Seems strange that an out of adjustment rack would be so symmetrical over 150 passes. Also the part isn't vertical it's a 5 degree draft so it is stepping out a bit on each pass as well.

As far as a line number well anywhere there is a G2/G3 arc. It does seem to be worse when the X is the dominant axis which lends credence to the out of adjustment theory in my mind.

There is only .004" backlash measured with a dial indicator on X and Y. Is this what you mean as far as adjustment? Seems strange that an out of adjustment rack would be so symmetrical over 150 passes. Also the part isn't vertical it's a 5 degree draft so it is stepping out a bit on each pass as well.

As far as a line number well anywhere there is a G2/G3 arc. It does seem to be worse when the X is the dominant axis which lends credence to the out of adjustment theory in my mind.

- Attachments

-

finish 4.txt.zip

finish 4.txt.zip- (200.31 KiB) Downloaded 659 times

- Derek

- Posts: 341

- Joined: Mon Sep 05, 2016 9:57 am

Re: Choppy motion on arcs

What kind of breakout board do you have? It's interesting that the Z and A axes' step signal is also negated. If the BOB works the same way on all outputs and the dirvers are also the same type then inverting the step signals on A axis may cause delays between the master and slave axes' movements.

- dezsoe

- Posts: 2093

- Joined: Sun Mar 12, 2017 4:41 pm

- Location: Csörög, Hungary

Re: Choppy motion on arcs

I have no idea why those were inverted. I fixed it but it made no difference in the cut. I recut the same section in the picture but removing .015" and the chop on the fresh area is lining up with the old area. I turned off the back lash comp and there was no change.

I've been looking at the mechanicals and can't see anything obvious. The Y axis has a slight roughness to it on a rapid jog but not at the frequency of the chop. A straight X or Y cut is smooth as silk. Every arc cut on it has the same chop and feels like the same frequency. I don't know what on a rack and pinion system would cause a rhythmic synchronized error like this.

I've been looking at the mechanicals and can't see anything obvious. The Y axis has a slight roughness to it on a rapid jog but not at the frequency of the chop. A straight X or Y cut is smooth as silk. Every arc cut on it has the same chop and feels like the same frequency. I don't know what on a rack and pinion system would cause a rhythmic synchronized error like this.

- Derek

- Posts: 341

- Joined: Mon Sep 05, 2016 9:57 am

Re: Choppy motion on arcs

On several occasions, I've seen posts from rack and pinion users that had "steps" on diagonal and circular cuts.

It may have something to do with the way those pinion drives force the pinion into the rack?

It may have something to do with the way those pinion drives force the pinion into the rack?

Gerry

UCCNC 2022 Screenset - http://www.thecncwoodworker.com/2022.html

UCCNC 2022 Screenset - http://www.thecncwoodworker.com/2022.html

- ger21

- Posts: 2714

- Joined: Sat Sep 03, 2016 2:17 am

Re: Choppy motion on arcs

Ok it was mechanical. I took apart the Y axis and the slide had a distinctive thump thump thump when I moved it. It uses roller bearings on flat bar and I cleaned the crap out of it and ran it again and it cut great. I had replaced the X axis with linear guides about a year ago so I guess I'll have to do the same for the Y if I'm going to do any kind of pattern work with it.

Thanks for all the help everyone. I'm so glad it was mechanical. That I understand:)

Derek

Thanks for all the help everyone. I'm so glad it was mechanical. That I understand:)

Derek

- Derek

- Posts: 341

- Joined: Mon Sep 05, 2016 9:57 am

Re: Choppy motion on arcs

The problem with rack and pinion drive is that if you apply too much force (e.g. spring pressure) to push the pinion in the rack then it will likely to make chops, because the pinion slips into the rack at a point and that causes a vibration. And if you apply too low force then the backlash will cause vibration and again there will be chops.

The real solution is to use 2 pinions which usually totally eliminates this type of problem, but at least it lowers it by factors.

The real solution is to use 2 pinions which usually totally eliminates this type of problem, but at least it lowers it by factors.

- cncdrive

- Site Admin

- Posts: 4887

- Joined: Tue Aug 12, 2014 11:17 pm

Re: Choppy motion on arcs

That may have been part of it as well. I had put a little extra tension on it a few days ago thinking that it would be a good idea but after hearing this that probably wasn't a good idea.

- Derek

- Posts: 341

- Joined: Mon Sep 05, 2016 9:57 am

10 posts

• Page 1 of 1

Return to General discussion about the UCCNC software

Who is online

Users browsing this forum: No registered users and 30 guests