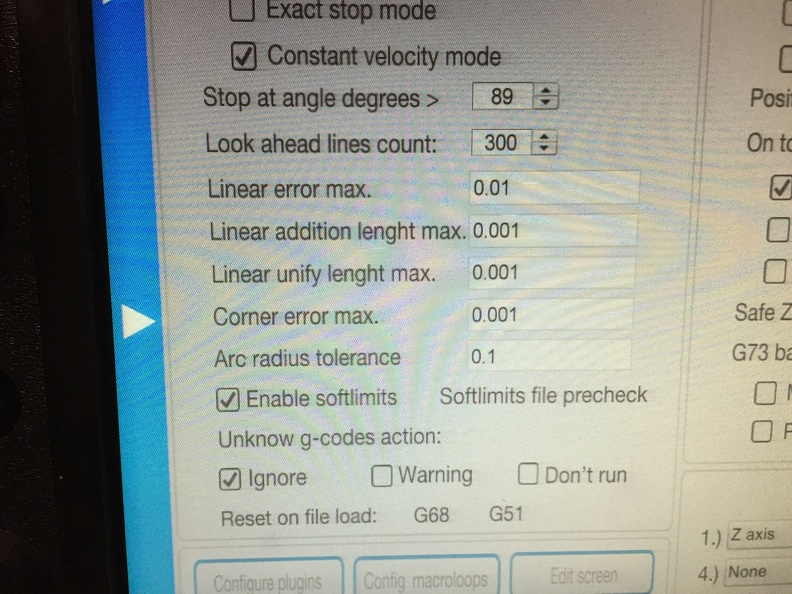

As Gerry said, linear unify and linear addition lengths are very low.

The addition length means that the software is not allowed to add longer line or arc segment than that to the lookahead process.

The unify length means that the total length of the unified segments can't be longer than that.

In both cases when the segment or the sum of segments is longer then the software is forced to deccelerate on the next endpoint, because this is what these parameters mean.

You can set these 2 parameters much higher in most cases, they can be even several inches long.

The issue a high value can cause is if you for example have a lower angle connection on the path than the set stop angle,

let's say (just a simple example) you have a square 90°connection and you set the stop at angle to 91° and e.g. that line is an outer contour, a side on the workspace which you want to be square,

then if the mentioned 2 parameters are longer than the side and the connection angle is lower then the stop at angle then the side will no more be square to the other sides,

because the software will look ahead into it and will optimise the path in a way that it will run off the path with upto the max. linear error parameter,

which in your case is likely still not a problem, because your linear error parameter is really low and the unparallelness will be only with the value of the linear error value, so the difference, the unparallelness will be small value.

However if the linear error would be also high and the above mentioned values would be used then the issue could become visible on the example toolpath.

Ofcourse setting the angle to 89°would also fix the issue at a 90˛connection even if the linear error would remain high.

I hope you guys understand what I'm trying to explain.