i got a problem with my CNC running an ETH300 5LPT.

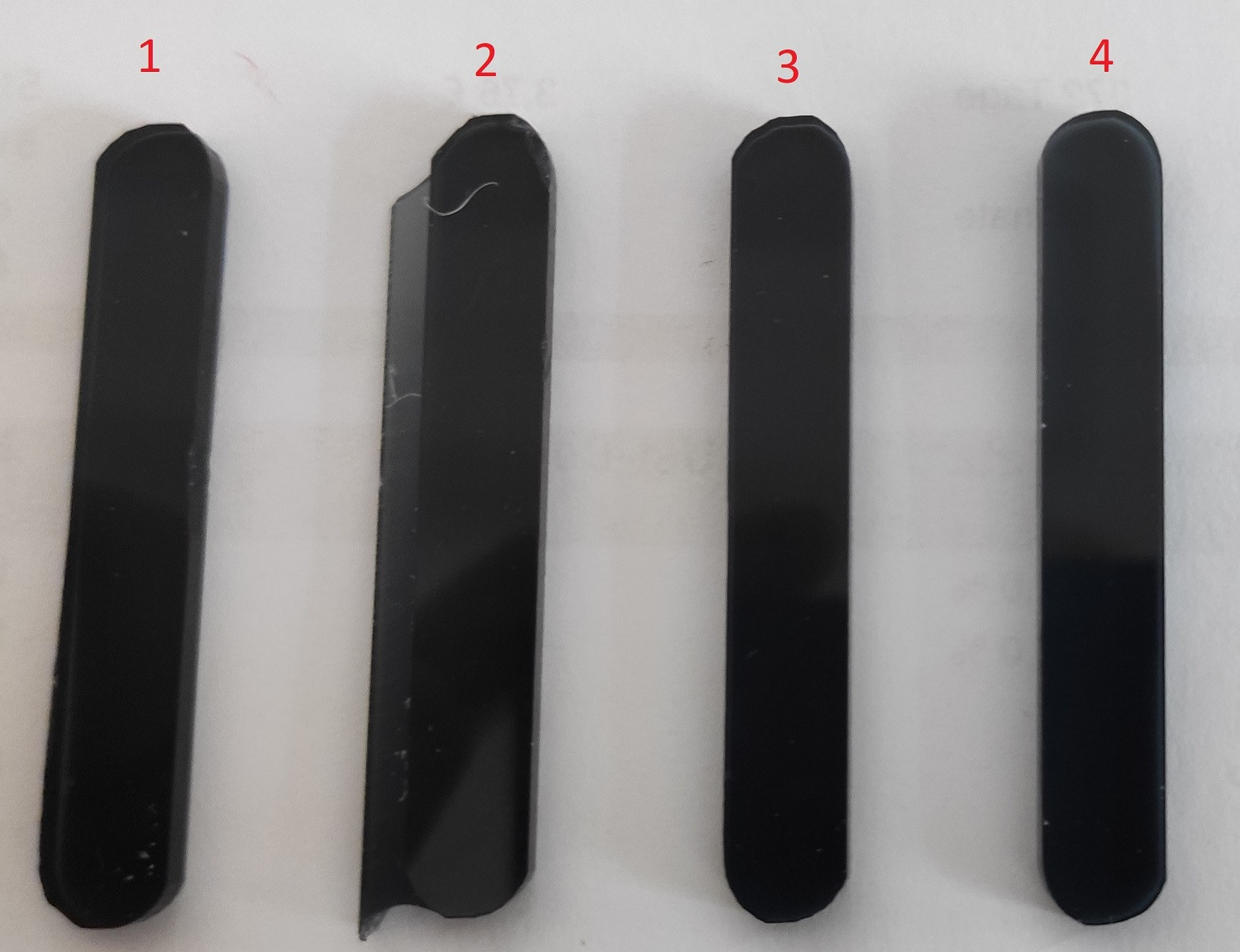

Circles/Arcs or non linear (combination of X and Y) movements seem to be very rough.

I use Fusion as a CAM software and tried the following so far:

in UCCNC:

Constant Velocity Mode ON/OFF

Acceleration of X and Y up to 1800mm\s2

in Fusion:

Smoothing enabled: Tolerance and Smoothing both at 0.05mm at the moment (to generate less lines of code and starve the controller)

Deactivated IJK mode in the Postprocessor so i only get polylines

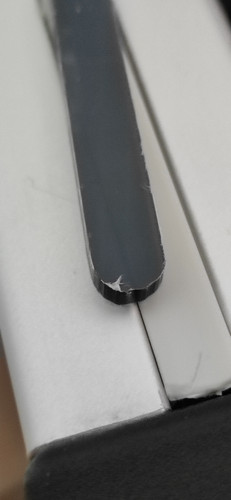

Nothing seem to help with the issue, see the picture of a Part i routed.