Learning Material for someone new to CNC

Hey CNCdrive and forum members,

First off I must say thanks to the creators. I purchased the UC400ETH and a license for UCCNC and so far the experience has been great.

I am a woodworker and somehow decided I needed to build a CNC Router. I have been building since October and have the Machine, Controller Box, Control Panel all working. Everything is new to me so I have been reading all the manuals, related manuals, cnczone posts, etc.

Here is where I am at today, and here are a few things that I didn't learn about anywhere. Hoping someone can point me to a good resource to learn some of these basic core concepts so I can be less confused.

I have most of my UCCNC v1.2037 software setup.

X,Y,Z Axis Pins, EStop, Limits/Home, Hotkeys for my panel.

I can jog each axis as designed.

Before I attach actual tools to the spindle I decided to chuck up a nice Sharpie pen and laid a roll of wrapping paper over the table bed. I found a website that let me convert some text into simple gcode. The max amount of Z travel is from 2 to -1. The letters come out nice (when I get the Z zeroed), but they are huge and also the feedrate is super slow. Even at 300%. I was running it line by line so I didn't get the initial popup like when you press Cycle Start. I later noticed I could set the feedrate in that popup. So while drawing the letters it is insanely slow, but when homing or moving to another location it is insanely fast. Also the safe Z says 25 which can't be possible on this machine. What does 25 mean? 25mm? What are the coordinates measured in ?

A little more background...

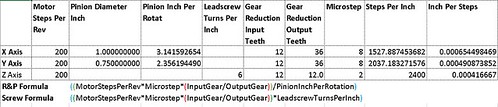

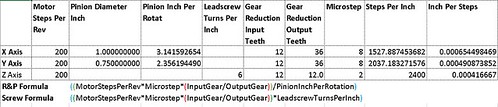

I completely understand zero for the X and Y axis and where home is. Z is another story. I keep thinking I have it at zero and then it tries to go way too far into the table, bending my Sharpies. I was reading some other posts and think I may have been misunderstanding the term "Units". When I built this machine, the author of the plans explained in great detail how to determine Steps per Inch, Inches per Step, Resolution, Inches per rotation... When I use the Calibration Tool to measure for Steps/Unit it comes out to 10x lower number than if I do the math.

Here are my math figures.

First off I must say thanks to the creators. I purchased the UC400ETH and a license for UCCNC and so far the experience has been great.

I am a woodworker and somehow decided I needed to build a CNC Router. I have been building since October and have the Machine, Controller Box, Control Panel all working. Everything is new to me so I have been reading all the manuals, related manuals, cnczone posts, etc.

Here is where I am at today, and here are a few things that I didn't learn about anywhere. Hoping someone can point me to a good resource to learn some of these basic core concepts so I can be less confused.

I have most of my UCCNC v1.2037 software setup.

X,Y,Z Axis Pins, EStop, Limits/Home, Hotkeys for my panel.

I can jog each axis as designed.

Before I attach actual tools to the spindle I decided to chuck up a nice Sharpie pen and laid a roll of wrapping paper over the table bed. I found a website that let me convert some text into simple gcode. The max amount of Z travel is from 2 to -1. The letters come out nice (when I get the Z zeroed), but they are huge and also the feedrate is super slow. Even at 300%. I was running it line by line so I didn't get the initial popup like when you press Cycle Start. I later noticed I could set the feedrate in that popup. So while drawing the letters it is insanely slow, but when homing or moving to another location it is insanely fast. Also the safe Z says 25 which can't be possible on this machine. What does 25 mean? 25mm? What are the coordinates measured in ?

A little more background...

I completely understand zero for the X and Y axis and where home is. Z is another story. I keep thinking I have it at zero and then it tries to go way too far into the table, bending my Sharpies. I was reading some other posts and think I may have been misunderstanding the term "Units". When I built this machine, the author of the plans explained in great detail how to determine Steps per Inch, Inches per Step, Resolution, Inches per rotation... When I use the Calibration Tool to measure for Steps/Unit it comes out to 10x lower number than if I do the math.

Here are my math figures.