Thread discussion here (mainly a list of THC's, but got onto the inner workings of THC's) http://www.plasmaspider.com/viewtopic.php?f=3&t=23286

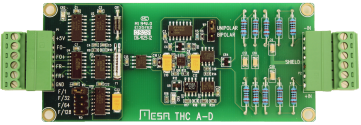

I came across a MESA THCAD which is available as two variants a 0-10V and a 0-300V Analog to Digital Converter (ADC).

US$69 + shipping

http://store.mesanet.com/index.php?rout ... uct_id=127

http://store.mesanet.com/index.php?rout ... uct_id=128

http://www.mesanet.com/pdf/analog/thcadman.pdf

I had not considered an ADC that output the analog voltage as a frequency before (knew of them, just did not see an application for it until now).

Firstly if anyone is considering this, I would recommend the 0-10V variant as it allows for more flexibility via adding an approprate additional resistor to increase the range of the ADC.

Apparently because this ADC uses Delta-Sigma voltage to frequency converson is is more noise immune than other ADC conversion options.

Bit of a write up here: https://www.maximintegrated.com/en/app- ... vp/id/1870

__________________________________________________________________________________________________________________________________________

Background waffle now out of the way, I noticed that the THCAD was able to to be used with an encoder input from the manual, given it outputs frequency which is proportional to the measured voltage.

The default output frequency is 100kHz to 1MHz (1:1 scale), although frequncy dividers are available at 32, 64, and 128.

Hence 1Mhz full scale will become 31,250Hz with a 32:1 divider jumper setting.

Having read in another post on encoders within the Hardware section of this forum, the maximum encoder input frequency is 1/2 the kernal frequency of the UC motion controller, 1Mhz is a little high, but ~32Khz is well within the realms of the UC motion controllers for an encoder input to provide ADC input for something like Torch Height Control.

There is a catch in that I cannot see at present how the z axis could be controlled by this (fast) as the plugin / macro loop is 20Hz, hence we would need for CNCDrive to provide access to a faster loop as a comparitor to be able to track the encoder input relative to the target encoder setting via some sort of a P, PI or PID loop.

It looked an interesting THC option though for integril THC via a simple PCB with good isolation.

Thoughts anyone?