I do not really understand it.

You saying that for example on a 10mm dia circle you feed around with for example 100mm/min feedrate and so the full circle circumference is 31.40mm and so the circle cutting will finish in 0.314 minutes.

Now you offset the circle from the outside with e.g. 5mm and so the circle diameter will become 20mm and you still want the tool to finish the job in 0.314 minutes?

Then the circle circumference is 62.80mm and so the feedrate would have to be doubles to 200mm/min to let the tool still finish in 0.314 minutes.

But hey, then your tool will be much more loaded, you programmed 100mm/min feedrate and you get double than that 200mm/min.

Who guarantees that your tool with the actual spindle speed can handle that and that it will not make too many chips which it can't move out and breaks your tool?!

I see this "feature" very unhandy and dangerous, probably this is why I have never seen this as a feature on any CNC controllers.

I beleive you that it is a feature on one strange controller, but it is not a standard feature for sure.

G41 / G42 feed compensation

22 posts

• Page 2 of 3 • 1, 2, 3

Re: G41 / G42 feed compensation

No you don't understand me.

You program a 20mm circle with 100mm/min feedrate. So in the gcode is a 20mm circle, no offset.

Then you select a tool from the magazin with 10mm diameter.

So the cutter compensation will use R5, so the actual path of the mill will be a circle of 10mm.

If that 10mm circle is still moved with 100mm feedrate, the 20mm circle, where the mill is actually cutting, is moving at 200mm/min.

So the feedrate needs to be slowed down by 50% in this example to be at the programmed 100mm/min, to prevent the mill of having too much chipload.

You program a 20mm circle with 100mm/min feedrate. So in the gcode is a 20mm circle, no offset.

Then you select a tool from the magazin with 10mm diameter.

So the cutter compensation will use R5, so the actual path of the mill will be a circle of 10mm.

If that 10mm circle is still moved with 100mm feedrate, the 20mm circle, where the mill is actually cutting, is moving at 200mm/min.

So the feedrate needs to be slowed down by 50% in this example to be at the programmed 100mm/min, to prevent the mill of having too much chipload.

- skillalot

- Posts: 7

- Joined: Sat Nov 03, 2018 7:53 pm

Re: G41 / G42 feed compensation

then- you program it at half feedrate  you know what its going to do when you program it ?

you know what its going to do when you program it ?

Uc300eth on router and mill.

UK uccnc powered machine sales. https://cncrouter.uk/atc-cnc-routers.htm

Automateanything/duzzit cnc/mercury cnc

UK uccnc powered machine sales. https://cncrouter.uk/atc-cnc-routers.htm

Automateanything/duzzit cnc/mercury cnc

- Battwell

- Posts: 827

- Joined: Sun Sep 25, 2016 7:39 pm

- Location: South Wales. Uk

Re: G41 / G42 feed compensation

The tool will have the same chipload, because the tool still moves with 100mm/min at it's center, no matter how much you offset the path. It will not move with 200mm/min like how you saying, it will not happen like how you think it will!

The feedrate is measured on the path, so it does not matter with what radius you offset the path it will still always move with 100mm/min on the path if you programmed F100.

The feedrate is measured on the path, so it does not matter with what radius you offset the path it will still always move with 100mm/min on the path if you programmed F100.

- cncdrive

- Site Admin

- Posts: 4717

- Joined: Tue Aug 12, 2014 11:17 pm

Re: G41 / G42 feed compensation

He Skillalot, welcome! Nice opening! Very interesting!

But shouldn't that be handled in the PP? Fusion for example.

But shouldn't that be handled in the PP? Fusion for example.

- kawarider

- Posts: 42

- Joined: Sun Jun 17, 2018 10:38 am

Re: G41 / G42 feed compensation

I think he missunderstands the definition of "Feedrate" is the problem here.

- cncdrive

- Site Admin

- Posts: 4717

- Joined: Tue Aug 12, 2014 11:17 pm

Re: G41 / G42 feed compensation

Ok, I will try to explain one more time, and then I give up

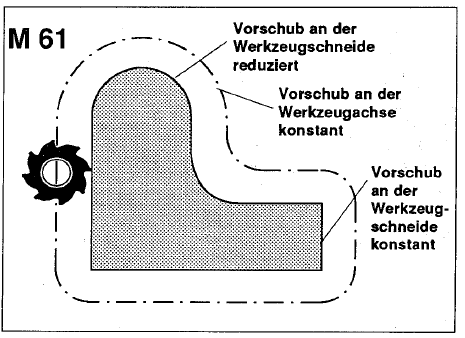

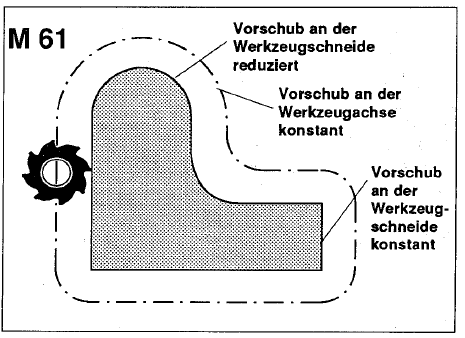

Let's look at the picture of the Deckel manual (more controllers have these functions, like heidenhahn etc as well, and I think even Edingcnc does it)

With conventional milling where you mill a slot, the cutting tool is cutting in the center of the mill (not only the center, but chipload is highest there).

With HSM milling you are not cutting with 100% of the diameter of the tool, but sideways where you take 20% of the tool diameter stepover for example, but at full cutting length. Highest chipload is at the outside of the tool.

The cam software makes the G-code with the dimensions of the black continue line, the exact size of what the part should be, and puts out a speed that's for example 100mm/min.

In the G code a tool is called, let's say T6 for example. And in the tool table is defined that T6 is a 10mm endmill for example.

The the cutter compensation offsets the path that the mill is doing with 5mm to the programmed path.

Now in the G code is only the speed for the continued black line, not the offset line.

In this example picture that would meen that on the arc on the top, the end mill would travel with the center over the broken line, with that 100mm/min that was in the G code. This means that the speed around the continued black line is much less. In this case not as big of a problem, chipload stays lower then it can handle, only the surface finish is different there.

On the arc inside the corner though, the speed on the continued black line would be much higher then the 100mm/min it travels over the broken line there.

Surface finish would again be differed, chipload would be much higher then allowed, and probably you destroy your cutting tool.

Now before the discussion where this should be adjusted, whether it is in cam software, or in the G41/G42 with a special function, please tell me you can see what I mean now.

And if you know any cam software that can do HSM milling, adjusts the feedrate throughout the whole program in corners etc, and is affordable, then let me know.

Let's look at the picture of the Deckel manual (more controllers have these functions, like heidenhahn etc as well, and I think even Edingcnc does it)

With conventional milling where you mill a slot, the cutting tool is cutting in the center of the mill (not only the center, but chipload is highest there).

With HSM milling you are not cutting with 100% of the diameter of the tool, but sideways where you take 20% of the tool diameter stepover for example, but at full cutting length. Highest chipload is at the outside of the tool.

The cam software makes the G-code with the dimensions of the black continue line, the exact size of what the part should be, and puts out a speed that's for example 100mm/min.

In the G code a tool is called, let's say T6 for example. And in the tool table is defined that T6 is a 10mm endmill for example.

The the cutter compensation offsets the path that the mill is doing with 5mm to the programmed path.

Now in the G code is only the speed for the continued black line, not the offset line.

In this example picture that would meen that on the arc on the top, the end mill would travel with the center over the broken line, with that 100mm/min that was in the G code. This means that the speed around the continued black line is much less. In this case not as big of a problem, chipload stays lower then it can handle, only the surface finish is different there.

On the arc inside the corner though, the speed on the continued black line would be much higher then the 100mm/min it travels over the broken line there.

Surface finish would again be differed, chipload would be much higher then allowed, and probably you destroy your cutting tool.

Now before the discussion where this should be adjusted, whether it is in cam software, or in the G41/G42 with a special function, please tell me you can see what I mean now.

And if you know any cam software that can do HSM milling, adjusts the feedrate throughout the whole program in corners etc, and is affordable, then let me know.

- skillalot

- Posts: 7

- Joined: Sat Nov 03, 2018 7:53 pm

Re: G41 / G42 feed compensation

If you are going to retrofit that old Deckel and want to use modern toolpath's this discussion seems to be usefull

- kawarider

- Posts: 42

- Joined: Sun Jun 17, 2018 10:38 am

Re: G41 / G42 feed compensation

Maybe I want to retrofit the old deckel yes. Mechanically it's like new, hours on the machine counter are 460 lol, machine from 1986.

The control it has now works perfect, only the memory is an issue. 3100lines of code max. That's pretty fast out of memory with HSM toolpaths.

But more then the Deckel, I want to build my own machine, and exploring my options first, software included.

The control it has now works perfect, only the memory is an issue. 3100lines of code max. That's pretty fast out of memory with HSM toolpaths.

But more then the Deckel, I want to build my own machine, and exploring my options first, software included.

- skillalot

- Posts: 7

- Joined: Sat Nov 03, 2018 7:53 pm

Re: G41 / G42 feed compensation

and I think even Edingcnc does it

The 12 pages in their manual covering G41/G42 don't mention it.

Good luck finding a control that supports this for under $5K, if you can find one at all.

Gerry

UCCNC 2022 Screenset - http://www.thecncwoodworker.com/2022.html

UCCNC 2022 Screenset - http://www.thecncwoodworker.com/2022.html

- ger21

- Posts: 2671

- Joined: Sat Sep 03, 2016 2:17 am

22 posts

• Page 2 of 3 • 1, 2, 3

Return to General discussion about the UCCNC software

Who is online

Users browsing this forum: Bing [Bot] and 9 guests